What is Induction Sealing?

When we talk of products from the manufacturing and supply industry, sealed packaging assumes a lot of importance. There is more than one reason for this. Businesses need to make sure that the products they sell have a secure lid. It makes them safe and fit for consumption.

One of the ways to package products is with the help of an induction sealer. In this article, we take a look at the induction sealing process and what benefits it offers.

How does the induction sealing process work?

-

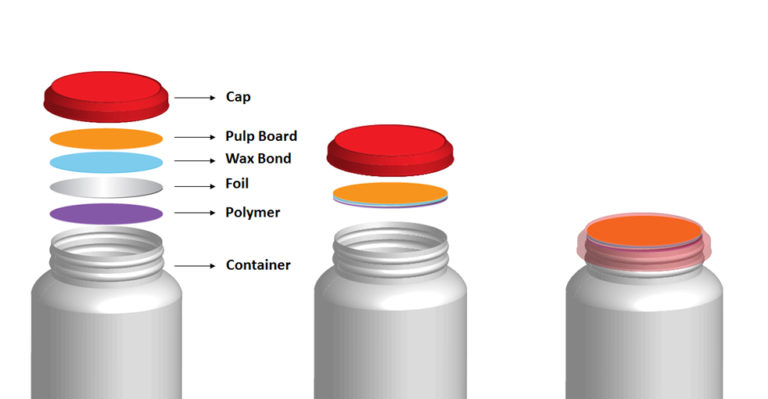

Also known as cap sealing, the induction sealing process is simple. Product containers with raw material and a cap with a foil liner pass through an induction sealer. As containers pass through the sealer, there is a transfer of energy from a controlled electromagnetic field.

The energy gets transferred to the foil liner(aluminium foil), which creates heat. The heat then melts the foil liner material. The liner then creates a durable hermetic seal on the container once it cools down. It creates an airtight seal where the product remains free from any contamination or leakage. There is also additional protection with counterfeiting and tampering.

- Here are some of the benefits of this technology.

- >> The freshness of a product makes it fit for consumption. The induction sealing technique ensures there is no product contamination by external contaminants. It also helps in increasing the durability and life of the product.

- >> Products can face spillage and get spoilt during transit if there’s no proper sealing. The sealing helps make them leakproof. Also, a seal on products helps customers understand that there was no tampering with the product.

- >> Regulatory bodies often have stringent norms about product packaging. With induction sealing, you can get tamper-resistant seals that help you meet compliance norms.

- >> An induction seal brings assurance into the mind of the consumer that the product meets quality standards. It directly helps meet customer satisfaction and improve it in the long run.

- >> Induction sealers have rapid electromagnetic induction emitted from the machine. The speed and frequency of the transmission enable quick sealing for faster production.

-

What products can an induction machine seal?

An induction sealing machine can seal almost all kinds of products from the cosmetics, pharmaceuticals, beauty care, and FMCG industries. It doesn’t matter whether the product is in a plastic or glass container. The sealing machine can seal them all.

You can also induction seal liquid, chilled, and dried products. Some of the examples include lubricant oils, beverages, herbs, powders, and much more.

How to choose the right container and liner materials?

Factors like application and material need consideration when choosing an induction liner. The liner usually has a one or two-piece assembly. The one-piece assembly comes with a foil laminate. The liner gets removed from the cap after the sealing process.

When it comes to two-piece assembly, it has an extra pulpboard layer and wax layer. The wax gets melted and absorbed into the pulpboard during the induction heating process. The pulp board layer offers better resealing when the foil liner gets removed.

Get your induction sealing machine today with Sigma CapSeal

Sigma CapSeal is a leading provider of sealing solutions for over four decades. We have a range of induction sealing machines that can fit your varied needs. If you are looking for reliable and cost-effective solutions to boost your business, look no further. Contact us today for a FREE inquiry about our machines.